+314-449-1459

Saint Louis

Cost Effective Design From Prototype To Production

At Water Jet St. Louis, we bring cutting-edge technology to life, offering top-tier CNC waterjet and milling services. With a commitment to quality and innovation, we deliver custom parts and components that meet your exact specifications, whether for industrial, commercial, or personal projects.

Utilizing state-of-the-art CNC waterjet and milling machines, we ensure accuracy down to the finest detail.

Whether it’s a one-off prototype or full-scale production, we tailor our services to your unique requirements.

Efficiency is key. We streamline the process to get your project delivered on time, every time.

From metals to composites and even ceramics, our expertise spans a wide range of materials to suit any project.

Water Jet St. Louis is a leading provider of CNC waterjet and milling services. With years of experience and a dedicated team of professionals, we have built a reputation for excellence in precision manufacturing. Our goal is simple: deliver exceptional quality, every time.

We aim to provide our clients with the highest standard of craftsmanship and service, pushing the boundaries of what’s possible with CNC technology.

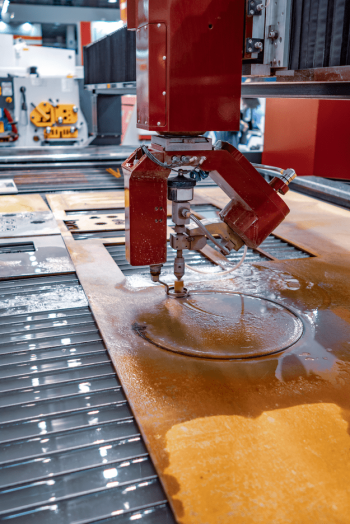

Our CNC waterjet cutting technology uses high-pressure water mixed with abrasive materials to cut through virtually any material with incredible accuracy. From metals and glass to stone and composites, our waterjet services are ideal for projects that require smooth, clean cuts without heat distortion.

High Precision: Tolerances up to ±0.001 inches

Material Flexibility: Cut through metals, ceramics, stone, plastics, and more

No Heat-Affected Zones: Maintain the integrity of the material

Eco-Friendly: Water-based cutting minimizes waste and energy usage

CNC milling offers precise, computer-guided machining to produce highly accurate parts from materials like metal, plastic, and wood. Our state-of-the-art CNC machines ensure high accuracy, efficiency, and consistency, making them ideal for both custom prototypes and large-scale production runs. Whether you need complex geometries or tight tolerances, we provide expert solutions tailored to meet your exact specifications.

Versatile Milling Capabilities: 3-, 4-, and 5-axis milling

Materials Expertise: From aluminum and steel to exotic metals and plastics

Fast Prototyping and Production: Rapid turnaround on custom designs

Precision Machining: Achieve tolerances up to ±0.0001 inches

Our CNC waterjet cutting technology uses high-pressure water mixed with abrasive materials to cut through virtually any material with incredible accuracy. From metals and glass to stone and composites, our waterjet services are ideal for projects that require smooth, clean cuts without heat distortion.

High Precision: Tolerances up to ±0.001 inches

Material Flexibility: Cut through metals, ceramics, stone, plastics, and more

No Heat-Affected Zones: Maintain the integrity of the material

Eco-Friendly: Water-based cutting minimizes waste and energy usage

CNC milling offers precise, computer-guided machining to produce highly accurate parts from materials like metal, plastic, and wood. Our state-of-the-art CNC machines ensure high accuracy, efficiency, and consistency, making them ideal for both custom prototypes and large-scale production runs. Whether you need complex geometries or tight tolerances, we provide expert solutions tailored to meet your exact specifications.

Versatile Milling Capabilities: 3-, 4-, and 5-axis milling

Materials Expertise: From aluminum and steel to exotic metals and plastics

Fast Prototyping and Production: Rapid turnaround on custom designs

Precision Machining: Achieve tolerances up to ±0.0001 inches

We proudly serve a wide range of industries, including:

No matter the complexity of your project, Water Jet St. Louis is ready to meet the challenge with high-quality, precision-crafted solutions.

Waterjet cutting is an industrial process that uses a high-pressure stream of water mixed with an abrasive material to precisely cut various materials, such as metal, plastic, foam, and composites. Modern waterjet cutters utilize CNC (Computer Numerical Control) technology to accurately position the water jet nozzle and enhance cutting precision.

Key advantages of waterjet cutting include:

Overall, waterjet cutting is a valuable industrial technique known for its versatility, precision, and ability to cut various materials without causing heat-related damage.

In essence, waterjet cutting combines accuracy, speed, and versatility to provide a superior cutting solution for various applications.

Waterjet cutting’s capabilities are vast, and at WaterjetSTL, we specialize in working with a variety of materials, including:

Metals: Titanium, tungsten, stainless steel, tool steel, and aluminum

Other materials: Stone, wood, composites, and various plastics

If you have a specific material in mind, don’t hesitate to ask. We’re happy to do a test cut to see if waterjet cutting is the right solution for your project.

We’re equipped to handle projects of all sizes. Whether you need a single small part or a large-scale production run, we have the capacity and expertise to meet your needs. Our waterjet cutting machines can accommodate various material sizes and thicknesses, ensuring we can tackle projects of any dimension.

Feel free to discuss your specific project requirements with us, and we’ll be happy to provide a tailored solution.

Two assure edward whence the was. Who worthy yet ten boy denote wonder.

Weeks views her sight old tears sorry.

"Water Jet St. Louis delivered exactly what we needed, on time and on budget. Their waterjet cutting service was flawless, and their customer service was exceptional."

We rely on Water Jet St. Louis for all our custom milling needs. Their attention to detail and quick turnaround have made them a trusted partner for our business